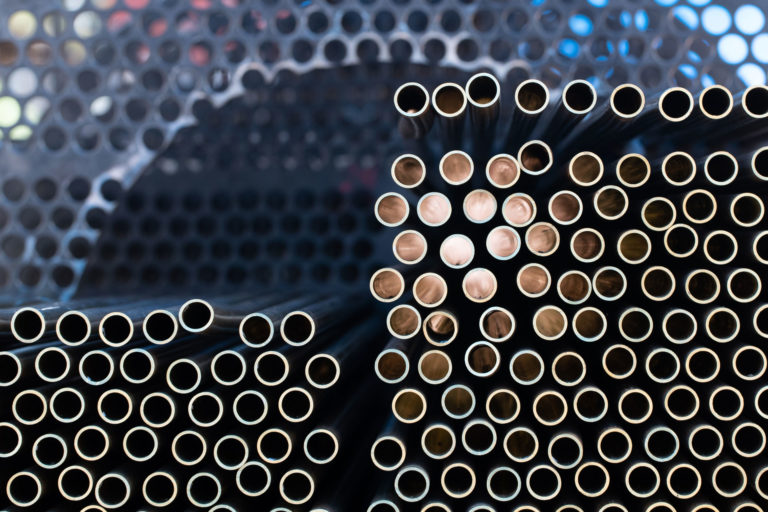

Super Alloys

KJ Tubing, Inc offers seamless titanium tube and zirconium tube for extreme applications. Applicable standard for titanium tube is ASTM B338, and for zirconium it is ASTM B523.

Titanium Tube Alloys

Due to titanium’s high tensile strength to density ratio, high corrosion resistance, and ability to withstand moderately high temperatures without creeping, titanium alloys are used in aircraft, armor plating, naval ships, spacecraft, missiles and the chemical industry.

Gr.1 Gr.2 Gr.3 Gr.7 Gr.9 Gr.11 Gr.12 Gr.16 Gr.17

Sizes:

OD 0.25″-5.5″, WT .012″-0.315″ Length ≤ 59′

OD 6.0-114mm, WT 0.3-8.0mm, Length≤18000m

Zirconium Tube Alloys

Zirconium is a corrosion-resistant material of choice in the chemical processing industry. Zirconium exhibits excellent resistance to corrosive attack in most organic and inorganic acids, salt solutions, strong alkalis, and some molten salts.

Gr 702

Sizes:

OD 0.25″ – 6″ WT 0.25 and up Length ≤ 40′

OD 6 – 152 mm WT 6mm and up Length ≤ 12 meters

Tantulum Tube Alloys

Tantalum is an excellent corrosion resistance material. Its corrosion resistance is better than Zirconium and can be compared with glass. Except fluorine, hydrofluoric acid, acidic solution containing fluoride ion, sulfuric acid and strong alkalis, tantalum will not degrade in most media. It can endure high-temperature and has superior erosion properties compared to other materials.

Ta – 2.5% W

Ta – 7.5% W

Ta – 10% W

Ta – 40Nb